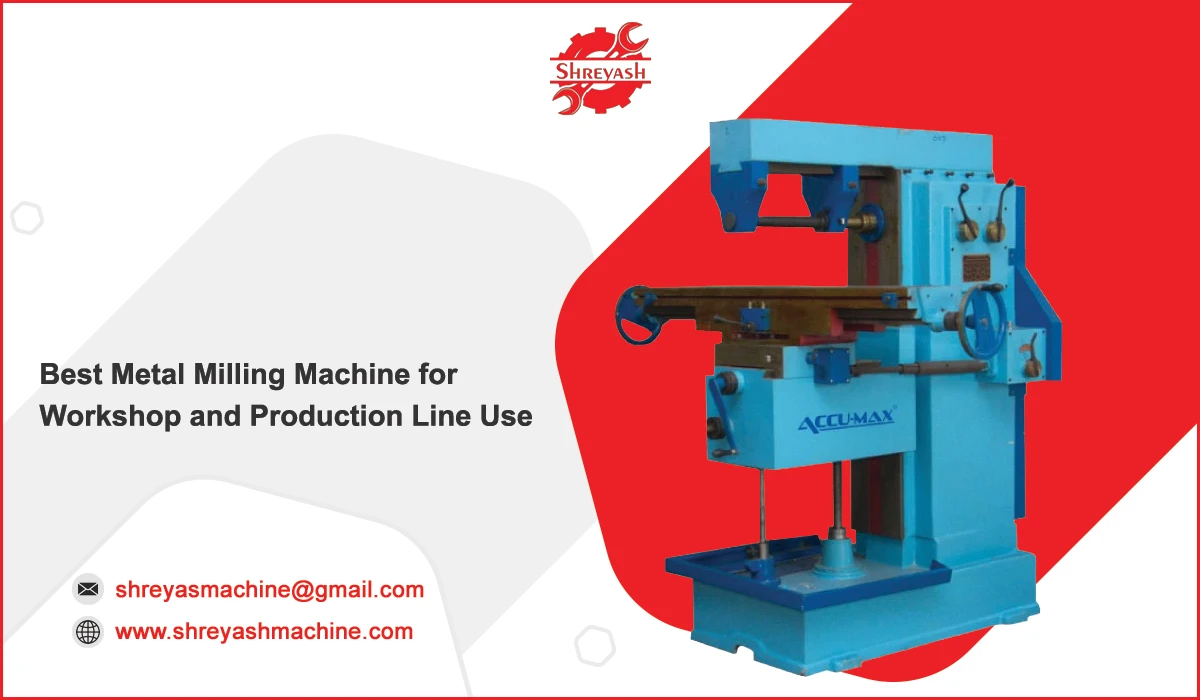

The Best Metal Milling Machine for Workshop and Production Line Use is designed to deliver high performance, precision, and durability for both small and large-scale metalworking operations. These machines are perfect for shaping, cutting, drilling, and finishing various types of metal with consistent accuracy. Built with a strong cast iron body and heavy-duty spindle system, they minimize vibration and ensure smooth operation during long production hours.

Whether used in a small workshop or a full production line, metal milling machines provide excellent flexibility for making components, molds, and industrial parts. Their advanced design allows easy control and adjustment of cutting speed and depth, making them ideal for precision engineering tasks. With the addition of CNC options, production efficiency and accuracy are further enhanced, helping reduce manual effort and time. These machines are compatible with various cutting tools and materials, ensuring superior result across multiple applications.

Rigid construction – Minimises vibration and ensures accuracy.

Powerful spindle with wide speed range – Handles different metals and tooling.

High precision & repeatability – Digital readouts or CNC control for consistent output.

Versatile tooling & operation – Face-milling, slotting, drilling, etc. with compatible tool-holders.

Easy maintenance & local support – Minimises downtime and keeps productivity up.

Production-ready design – Suitable for shop layout, power supply, chip/coolant handling.