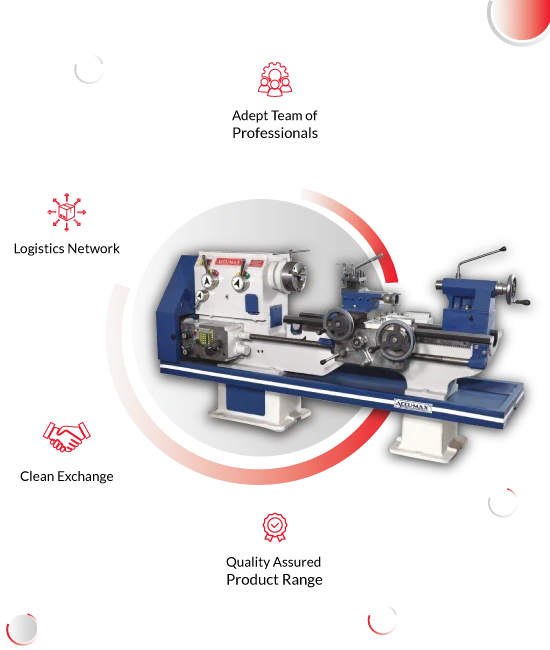

Extra heavy duty lathe machines are designed for the toughest industrial applications, offering unmatched strength, durability, and accuracy for machining oversized and heavy component.

Built with massive bed structures, powerful spindles, and precision-engineered gear systems, these machines are ideal for steel plants, shipbuilding, oil & gas, railway workshops, and large-scale fabrication units.

In 2025, the latest models come equipped with advanced technology such as digital readout systems, automatic feed mechanisms, hardened alloy guideways, and energy-efficient motors to deliver superior performance while reducing operational cost.

Their ability to perform continuous heavy turning, boring, drilling, facing, and threading on extra-large workpieces makes them a must-have for industries where reliability and productivity cannot be compromised.

Manufacturers have also focused on operator safety and ease of use, integrating ergonomic controls, advanced lubrication systems, and optional CNC features to enhance efficiency.

These machines not only ensure long service life but also significantly boost production capacity, making them a smart long-term investment.

In this guide, we highlight the latest extra heavy duty lathe machine models, explore their advanced features, and share expert reviews to help you choose the best machine for your workshop. Order now to get the latest technology at the best price and maximize your industrial performance.