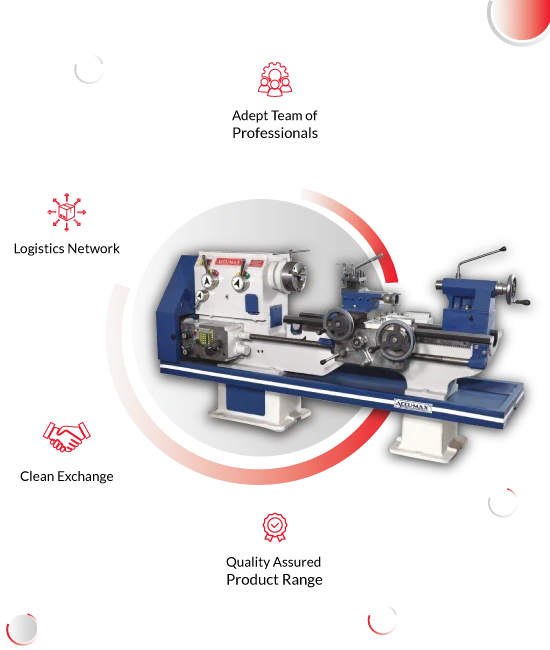

Medium duty lathe machines are the backbone of many industries, providing the perfect balance between power and precision for handling a wide range of machining task.

Built with stronger spindles, rigid beds, and advanced control systems, these machines are designed to perform heavy turning, threading, facing, drilling, and boring operations with ease and accuracy.

In 2025, medium duty lathes are in high demand across workshops, tool rooms, automobile industries, and general engineering units, as they offer long-lasting durability and high performance at competitive prices.

With their ability to work continuously on medium to large-sized components, these lathes ensure consistent production output, minimal downtime, and reduced operator fatigue thanks to ergonomic design and safety features.

Many of the latest models now include hardened guideways, precision gearboxes, energy-efficient motors, and digital readout systems for enhanced accuracy.

Whether you are a growing manufacturer or an established industrial unit, investing in a reliable medium duty lathe machine guarantees efficiency, quality, and profitability.

This guide highlights the top 5 models, their standout features, and why they are the smart choice for industrial operations in 2025. Don’t miss out—explore the options and order now to take advantage of the best deals and save big on your investment!